Your Cart is Empty

May 21, 2022 11 min read

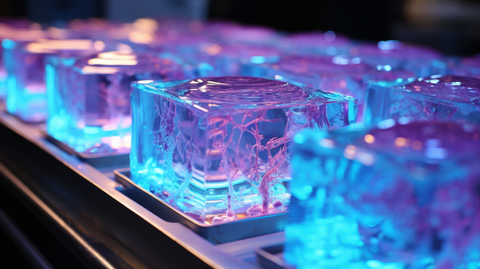

Check out our black light collection!

Tricky but beautiful, learn the intricate process of drying your masterful resin designs with UV light.

Working with resin is a creative process. With each layer, you form unique designs with your stamp of approval on them. Once your layers of liquid resins are set, the next question becomes how to make your precious liquid designs permanent. Say hello to drying.

Drying resin can be tricky, but UV light can make it much easier. UV light is a popular method for curing resin due to its efficiency and speed. In this article, you will learn how to dry resin with UV light, including the science behind the process and the steps to follow.

Whether you're a novice eager to embark on your first resin adventure or a seasoned artist seeking to refine your skills, join us as we shed light on the art and science of resin drying and unlock the potential to transform your resin creations into dazzling works of art.

Resin is a synthetic material that is used in many applications, including 3D printing. Resins are typically cured using UV light, which is a type of electromagnetic radiation with a wavelength between 10 and 400 nanometers. UV light can cure resins because it causes a chemical reaction that hardens the material.

UV-curing resin is a type of resin that is specifically designed to cure under UV light. This resin type is often used in 3D printing because it can be cured quickly and accurately using a UV light source. Epoxy resin is another popular type of resin that can be cured using UV light.

When working with resin, it is important to understand the material's properties and how it reacts to UV light. Some resins may require longer exposure times to cure properly, while others may require a specific wavelength of UV light. It is also important to consider the thickness of the resin layer, as thicker layers may require more UV exposure to cure completely.

Understanding the relationship between resin and UV light is crucial for achieving successful resin prints and ensuring that the material is cured properly. You can easily achieve high-quality resin prints by obeying manufacturer guidelines and experimenting with exposure times and UV light sources.

When you mix resin and hardener, a chemical reaction occurs, causing the mixture to harden over time. This process is called curing and can take anywhere from several hours to several days. However, by exposing the resin to UV light, you can significantly reduce the curing time.

UV curing uses UV rays to trigger achemical reaction in the resin, which causes it to harden. The UV rays interact with a catalyst in the resin, which starts the curing process. The resin will begin to harden almost immediately after exposure to UV light, making it an ideal method for fast-curing resin.

The curing time for resin with UV light varies depending on the resin type and the UV light's strength. Generally, the stronger the UV light, the faster the curing time. Temperature can also affect the curing time. Higher temperatures can cause the resin to cure faster, while lower temperatures can slow down the curing process.

UV curing is a popular method for hardening resin because it's fast and efficient. It's also a great option for those who don't have access to a heat source or who want to avoid using heat to cure their resin. Just be sure to use the appropriate UV light for your resin and follow the manufacturer's instructions for curing time and temperature.

Drying resin with UV light is a quick and easy process. Here are the steps to follow:

Always wear protective gear when working with UV light, and avoid exposing the resin to direct sunlight or low temperatures during the curing process. With the right tools and techniques, you can easily create beautiful resin projects at home using UV light.

When working with resin and UV light, taking proper safety measures and precautions to protect yourself and others is important. Here are some tips to keep in mind:

By taking these safety measures and precautions, you can minimize the risks of working with resin and UV light. Always prioritize safety and follow the manufacturer's instructions to ensure a successful and safe project.

One of the reasons for resin’s notoriety is its ability to work in multiple use cases. You may consider using resin in your projects if you're into art and jewelry making. Resin is a versatile material that can be used to create diverse objects, from pendants and sculptures to molds and more.

One of the benefits of using resin is that it can be dried quickly using UV light. This means you can create intricate and detailed designs without waiting for the resin to dry naturally.

To start with resin art and jewelry making, you'll need a few supplies, including resin, a silicone mold, and a UV light. You can find these supplies at most craft stores or online.

Once you have your supplies, you can start creating your designs. Pour the resin into the silicone mold and use a toothpick or small brush to create your design. Once you're happy with your design, place the mold under the UV light to dry the resin.

Resin is a great material to work with because it's easy to use and can be precast into any shape or design you desire. Whether you're creating pendants, sculptures, or other objects, resin is a great choice for your projects.

Overall, using UV light to dry resin is a great way to speed up the drying process and create beautiful and intricate designs. With routine practice and creativity, you can produce stunning pieces of art and jewelry that will surely impress you.

If you're experiencing issues when drying your resin with UV light, don't worry. There are several common issues that can arise during the process, but they can be easily fixed. Here are some tips to help you troubleshoot:

If your resin is sticky after drying, it may need to be cured longer. Try curing it for a longer period of time or using a higher-wattage UV light. If this doesn't work, you may need to use a different type of resin that is less prone to stickiness.

If your resin is still uncured after drying, it may be due to the choice of resin, the proportion of hardener, or the wattage-level of UV light. First, make sure you use the correct resin type for your project. Also, ensure that you are using the correct amount of hardener and that you are mixing it thoroughly. If your resin is still uncured after trying these steps, you may need to use a stronger UV light or cure it for longer.

If your resin is too soft after drying, it may be due to several factors. First, ensure you are using the correct ratio of resin to hardener. Also, ensure that you are mixing it thoroughly. If your resin is still too soft after trying these steps, you may need to use a different type of resin that is less prone to softness.

If your resin is tacky after drying, it may be due to several factors. First, ensure you are using the correct ratio of resin to hardener. Also, ensure that you are mixing it thoroughly. If your resin is still tacky after trying these steps, you may need to use a different type of resin that is less prone to tackiness.

If you have air bubbles in your resin after drying, it may be due to a few different factors. First, ensure you mix your resin thoroughly and slowly to avoid introducing air bubbles. Also, try using a heat gun or torch to remove any bubbles that may have formed. If your resin still has air bubbles after trying these steps, you may need to use a different type of resin that is less prone to air bubbles.

Quality should be your top priority when choosing the right resin for your project. Look for resins that are specifically designed for UV curing, as these will produce the best results. Additionally, consider the type of hardener you will use, as this can affect the curing process.

When selecting a UV light, a few key factors must be remembered. First, consider the wavelength of the light. UV lights typically emit UVA or UVB wavelengths, with UVA being the most common. Look for a light that emits a wavelength that is compatible with your resin.

Another important factor to consider is the wattage of the UV light. Higher-wattage lights will cure your resin quicker but may also be more expensive. A lower-wattage light may be better if you work on a budget.

Finally, consider the price and output of the UV light. UV flashlights are a popular choice for small projects, as they are reasonably cheap and easy to use. However, if you are working on a larger project, you may need a more powerful UV light with a higher output.

Choosing the right resin and UV light is essential for achieving the best results. You can ensure that your project succeeds by considering factors such as quality, hardener, wavelength, wattage, and price.

To get the best value out of your resin products, you need to embrace healthy maintenance practices. Here are some tips to help you do just that:

By following these simple steps, you can help ensure that your resin and UV light equipment lasts as long as possible and continues to produce high-quality prints.

When using UV light to dry resin, there are some sophisticated techniques and tips that can help you achieve the best results and give you a finish that’s a little better than expected. .

First, consider using a quick cure additive to speed up the curing process. This can reduce the time it takes for the resin to dry and improve the overall finish of your project.

If you want to add pigment to your resin, use a high-quality product specifically designed for use with UV light. This will ensure that the pigment does not affect the curing process or cause any yellowing over time.

Another tip is using an accelerator to speed up the curing process further. This can be particularly convenient if you are working on a large project or need to finish your work quickly.

To prevent yellowing over time, make sure to use a high-quality UV-resistant resin. This will help to protect your project from the damaging effects of sunlight and other environmental factors.

Mastering the art of drying resin with UV light is a transformative skill for any resin enthusiast or artisan. As we've explored in this comprehensive guide, the process is versatile and efficient and offers a world of creative possibilities. Whether you're crafting intricate jewelry pieces, designing stunning artwork, or fashioning unique household items, UV resin drying opens up a realm of endless potential.

By understanding the key principles, safety precautions, and best practices outlined in this article, you're well on your way to achieving impeccable results. Patience and precision are your greatest allies when working with UV resin. Take your time, experiment with various techniques, and don't be afraid to push the boundaries of your creativity.

In your resin projects, you're not just working with a material; you're capturing moments, emotions, and imagination in a tangible form. Embrace the learning journey, and let the UV light illuminate your path toward resin mastery.

The best UV light for curing resin is a UV LED light. It emits a specific wavelength of light that reacts with the photoinitiator in the resin, causing it to harden. UV LED lights are more energy-efficient, longer-lasting, and emit less heat than traditional ones.

The amount of time it takes for resin to dry with UV light depends on the resin layer's thickness and the UV light's strength. Generally, it takes about 2-5 minutes to cure a thin resin layer with a UV LED light. Thicker layers may require multiple passes or longer curing times.

Yes, you can use a UV light to dry resin. UV light is one of the most effective ways to cure resin quickly and efficiently. However, it's important to use the correct type of UV light and follow the manufacturer's instructions carefully to ensure optimal results.

Yes, UV light hardens resin by activating the photoinitiator in the resin, causing it to cross-link and form a solid material. UV light is commonly used to manufacture various products, including coatings, adhesives, and dental materials.

Yes, you need a UV light to cure epoxy resin. Epoxy resin contains a photoinitiator that requires UV light to activate and harden. Without UV light, the epoxy resin will remain liquid and not cure properly.

To dry resin earrings, you will need a UV LED light and a small container to hold the earrings. Place the earrings in the container and position them to expose them to UV light. Cure the resin for the recommended time, and then remove the earrings from the container. Clean any residue with a soft cloth and enjoy your newly cured resin earrings.